Customized Material Conveying Solutions for Chemical Plants

Customized Material Conveying Solutions for Chemical Plants** Precision-enginee

Customized Material Conveying Solutions for Chemical Plants**

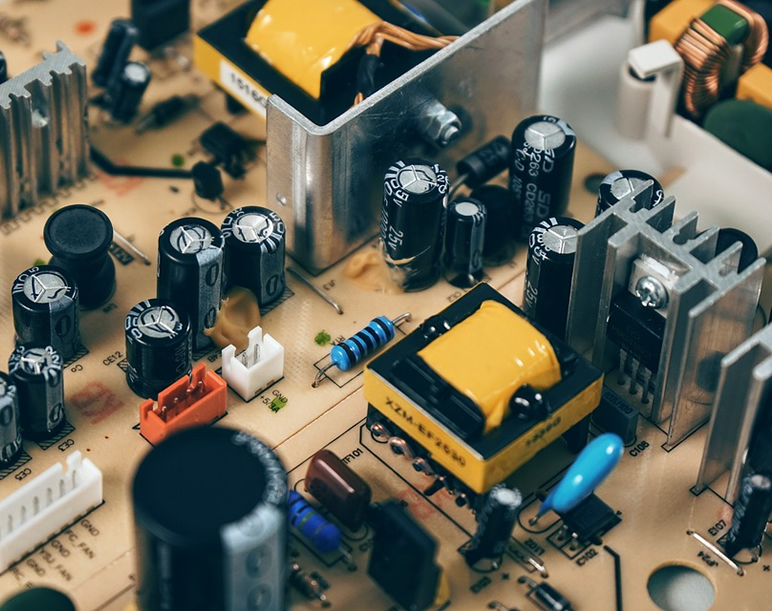

Precision-engineered stainless steel transfer pumps for specialized industrial applications*

Core Service

LEVIN delivers tailored material conveying systems for chemical production facilities, designed to handle diverse fluid properties including high-viscosity substances, corrosive media, and temperature-sensitive compounds.

**Customization Process**

1. **Parameter Analysis**

- Viscosity profiling (0.1-50,000 cP range)

- Distance optimization (50-500m pipeline configurations)

- Flow rate calibration (5-200 m³/h throughput)

2. **Pump Engineering**

- 316L/904L stainless steel construction (ASME BPE compliant)

- Seal-less magnetic drive technology (Zero leakage guarantee)

- Explosion-proof motor options (ATEX/IECEx certified)

3. **Performance Validation**

- CFD simulation for turbulent flow reduction

- 500-hour continuous stress testing protocol

**Technical Advantages**

- **Material Compatibility**

Handles acids, alkalis, polymers, and shear-sensitive suspensions

- **Energy Efficiency**

Variable frequency drives (VFD) reduce power consumption by 30-45%

- **Safety Compliance**

Integrated pressure relief valves & real-time viscosity monitoring

**Industry Applications**

✔ Petrochemical catalyst transfer

✔ Polymer resin transportation

✔ High-purity pharmaceutical intermediates

**Why Choose Us?**

*"From Rheology to Reliability – Your Complete Conveying Partner"*

- 12+ years in chemical pump experience

- CE/PED/API 685 certifications

- 360° after-service: Remote diagnostics + on-site maintenance

This version combines technical specifications with industry-specific terminology while highlighting safety and efficiency. Let me know if you need to emphasize particular certifications or add throughput capacity metrics!

-

Previous:上一篇:没有了

-

Next: